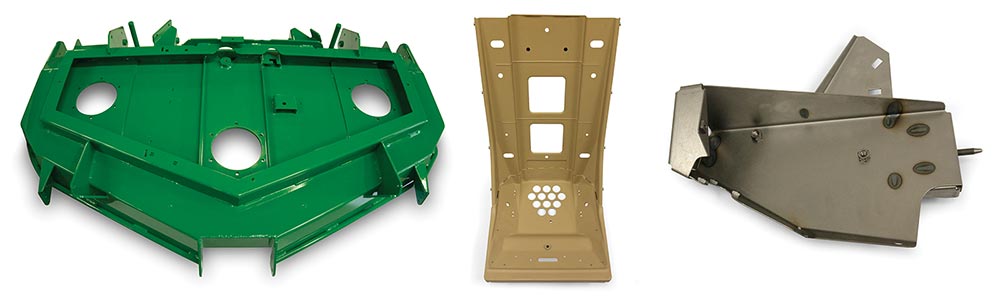

At K-TEK, approximately 40% of the parts we ship go through our Welding Department. These parts range from simple brackets with threaded nuts welded together – up to large commercial mower decks and other mechanical assemblies, some more than 100 pounds. Many of these weldments and assemblies are then plated or painted, which becomes both structural and cosmetic in their applications.

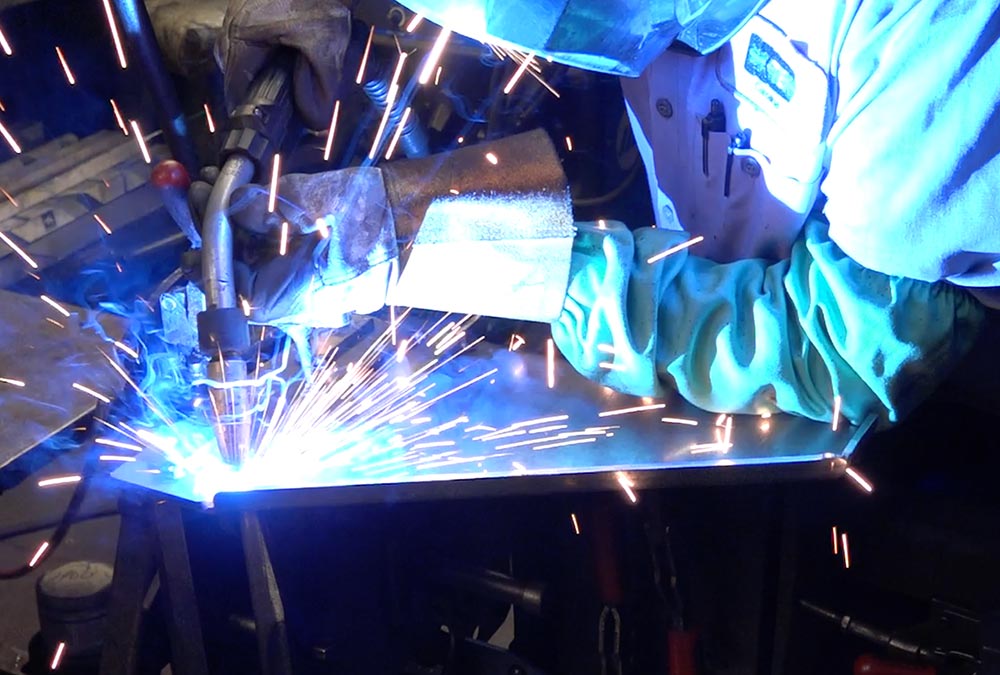

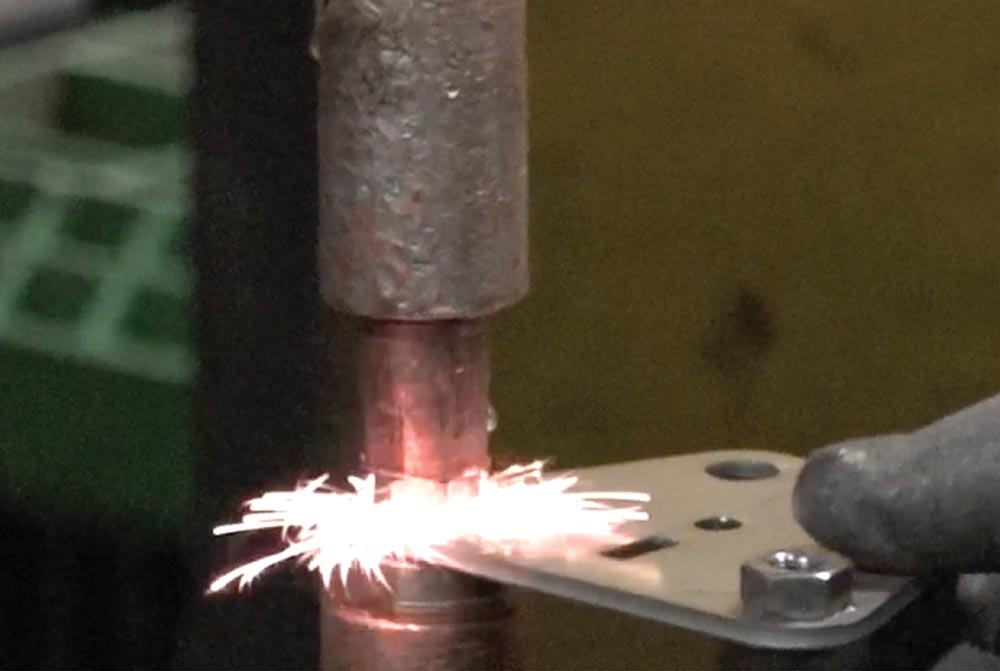

Video preview: This short video shows K-TEK Robotic welding in action. Both K-TEK North Carolina and K-TEK Wisconsin facilities are fully equipped with robotic welding cells and additional support equipment. Interested in seeing our complete capabilities video? Click Here.

K-TEK engineers are creative and solve difficult weldment designs and fixturing problems for robotic and manual welding setups. K-TEK has expertise in all forms of welding, and we combine this competency with our experienced welders, customer-structured teams and program managers to handle your projects/account.

K-TEK employs a variety of welding capabilities to meet the needs of our customers. These capabilities include:

K-TEK North Carolina and K-TEK Wisconsin facilities have a wide range of welding systems and equipment. These include Robotic Welders, Spot Welders, 3-phase Spot Welders, MIG Welder, and Syncrowave Welders. When needed K-TEK is willing to invest in the newest technology and automation.

K-TEK welds both big and small components and include:

Mower Decks, Lawn & Garden Assemblies, ATV Assemblies, Snowmobile Assemblies, Class 8 Truck Assemblies, Mechanical Weldments, Electronic Weldments and more.

K-TEK is a division of Griffiths Corporation which was founded in Minnesota as a short run metal stamping company in the mid-1960's.

K-TEK Wisconsin started in the early 1980's and grew out of their customer's need for a full-service supplier.