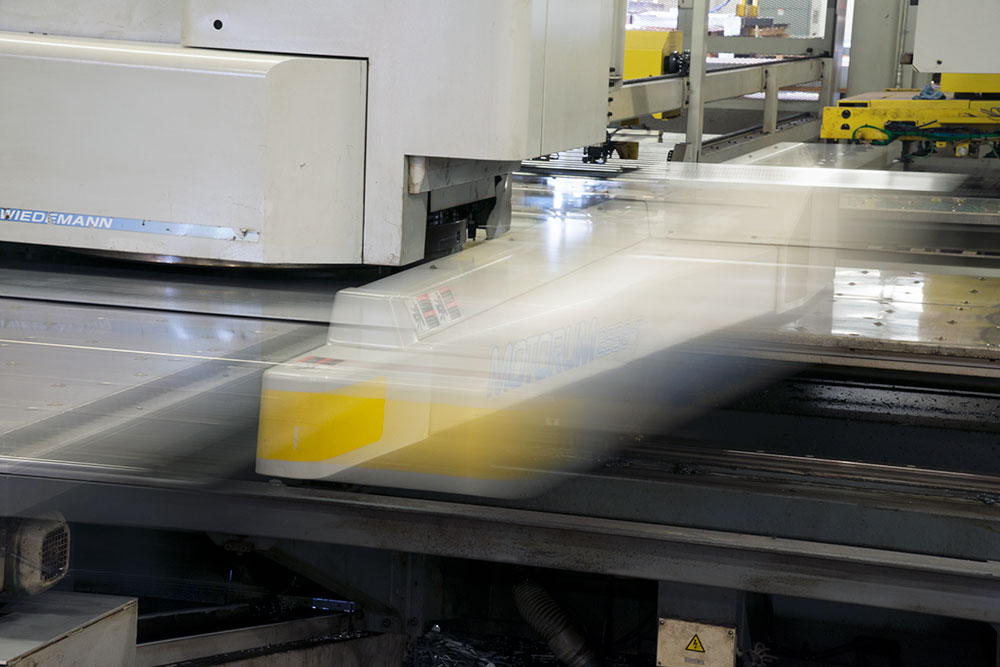

K-TEK CNC Turret punch presses are high speed and produce intricate shapes and designs in a wide range of materials and thicknesses. The sheet metal is placed between the punch and die mounted in the turrets and the table rapidly and smoothly moves the sheet to the proper position. With stroke speeds up to 600 per minute, K-TEK can produce your prototype or low volume parts quickly.

K-TEK CNC Turret Punch presses have fully stocked libraries of tooling stored inside the rotary turret as well as off-line for specific requirements of each project. Each turret press is capable of producing a wide range of shaped holes, extruded holes, louvers, tabs and knock-outs, and forms. K-TEK can customize virtually any part design with special tools to emboss logos, scribe serial numbers and more. When additional fabrication is needed K-TEK has a full array of equipment for bending, welding, staking, pem setting and secondary operations.

Both K-TEK facilities in North Carolina and Wisconsin are supported by an in-house group of highly skilled engineers who import your CAD design file and setup the most efficient way to punch the parts. Final sheet metal parts are maximized by proper part nesting, sheet configuration and minimizing tooling changes for machine up-time.

K-TEK uses both Amada and Wiedeman turret presses at our two plant locations. Each press brand has superior capabilities over each other and are leveraged to their fullest for each part design and run.

K-TEK is a division of Griffiths Corporation which was founded in Minnesota as a short run metal stamping company in the mid-1960's.

K-TEK Wisconsin started in the early 1980's and grew out of their customer's need for a full-service supplier.