K-TEK offers progressive die stamping that uses a single die to progressively create your custom parts as the metal strip travels through the die. By combining multiple operations into one tool our customers save on material usage and reduced labor costs, to create a less expensive part. Both K-TEK Wisconsin and K-TEK North Carolina plants have complete progressive stamping capabilities.

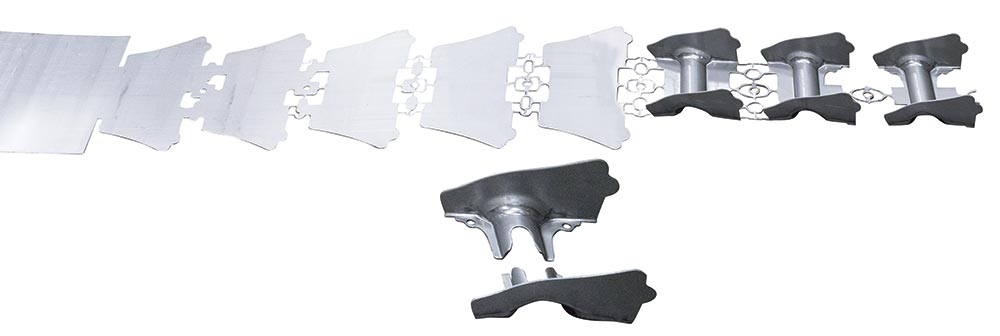

Video preview: See first-hand how K-TEK uses progressive stamping to produce a two-piece component. Watch as the system feeds from right to left and drops off completed parts after ten hits.

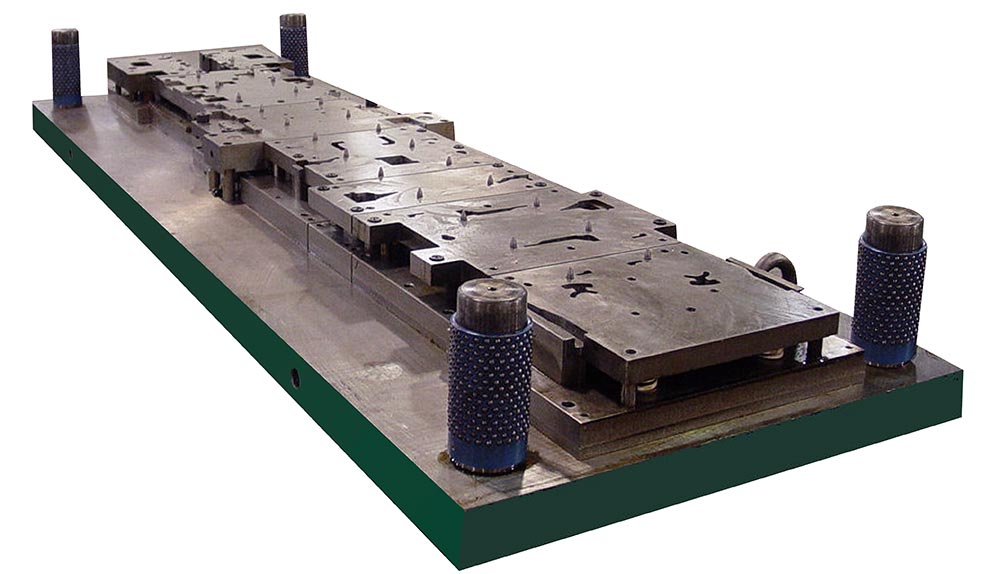

K-TEK designs, builds and maintains all progressive tooling in-house. K-TEK Wisconsin and K-TEK North Carolina have complete tooling departments.

The material coil and feeding system pushes the sheet metal through each station of the progressive stamping die. Each station performs one or more operations until each final part is stamped. At the final station a cutoff operation is performed separating the finished parts from the carrying web. The final components and the remaining scrap are separated into appropriate bins.

The part example shown above provides a visual of how the component shape is punched, formed, bent and the features progressively accomplished through each tooling stage. The final result is two-piece mating component.

K-TEK is a division of Griffiths Corporation which was founded in Minnesota as a short run metal stamping company in the mid-1960's.

K-TEK Wisconsin started in the early 1980's and grew out of their customer's need for a full-service supplier.