K-TEK offers a variety of assembly capabilities ranging from simple bench assembly to complex robotic assembly operations. We tailor our processes to fit the assembly and the production requirements – whether it needs a specially designed work cell or full-run production lines. To meet your fastening requirements K-TEK offers extensive options for joining techniques including all types of welding, riveting, staking, and bonding.

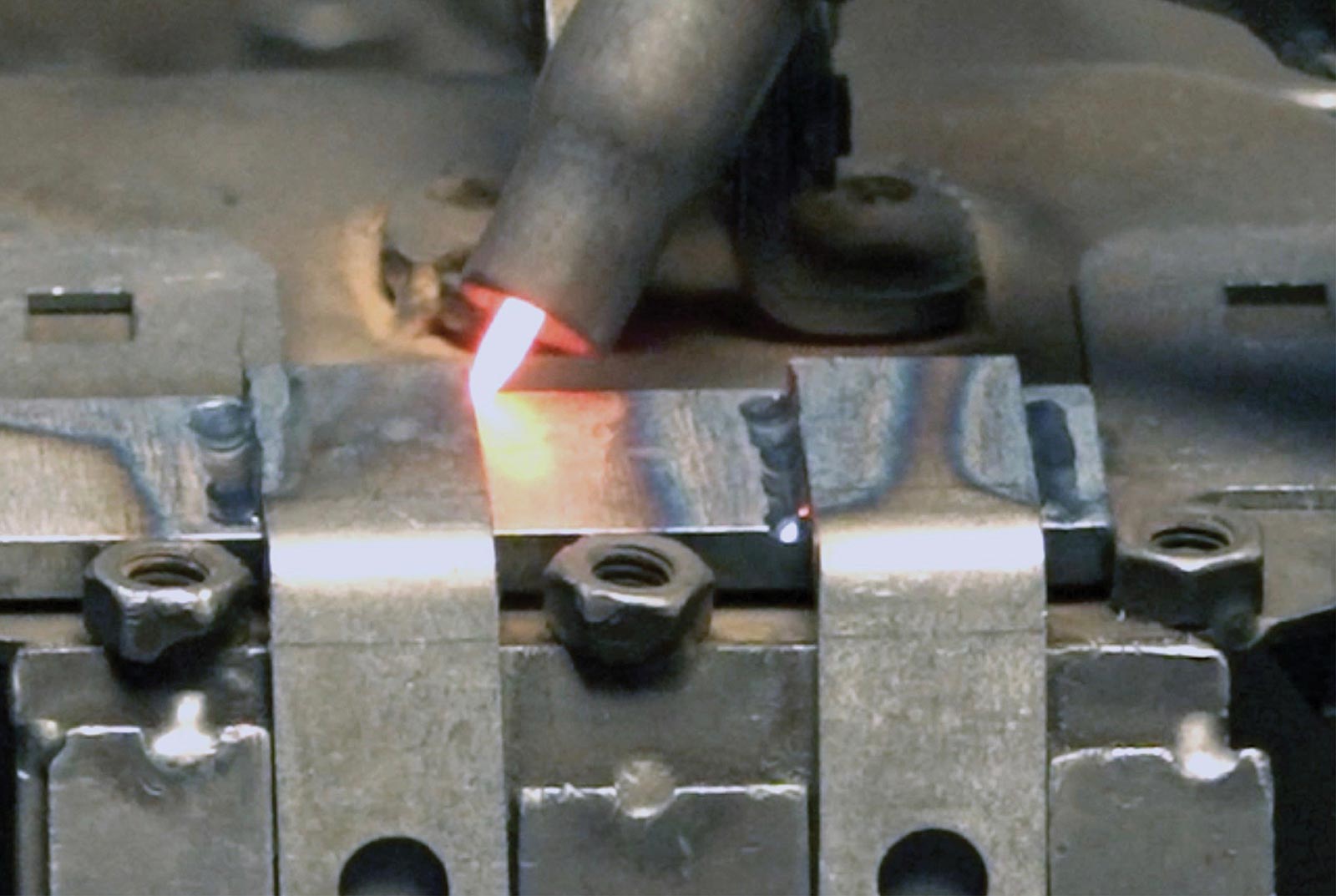

Video preview: This short video details a mechanical throttle assembly system. K-TEK also utilizes robotic systems and welding capabilities to assemble a wide range of fabrications, stampings, wire forms and laser processed components.

Our plant floors at both facilities in North Carolina and Wisconsin have capabilities for producing weldments, bonding, and riveting enclosures, frames, cabinets and more. We focus on building higher-level assemblies of mechanical parts and commonly perform hinge and door mechanisms.

K-TEK goes beyond only assembly and include:

PEM setting, Staking, Insertion, Painting, Plating and custom packaging, skidding, and crating right off the assembly line.

We have the assembly experience to take your project from start to finish quickly and cost-effectively.

Whether it’s a throttle assembly, filtration assembly or Wire and Sheet metal assembly, K-TEK has the experience, resources, and commitment to solving your assembly needs cost-effectively.

K-TEK is a division of Griffiths Corporation which was founded in Minnesota as a short run metal stamping company in the mid-1960's.

K-TEK Wisconsin started in the early 1980's and grew out of their customer's need for a full-service supplier.