K-TEK has 3-D wire forming equipment to fulfill our customers’ requirements from round and square wire. With K-TEK’s flexible range of manufacturing capabilities we can meet a wide variety of wire designs, including secondary operations including drilling, swedging, piercing, welding and assembly. Whether it’s for a long or short production run we meet your needs with 3D wire bending for all your applications.

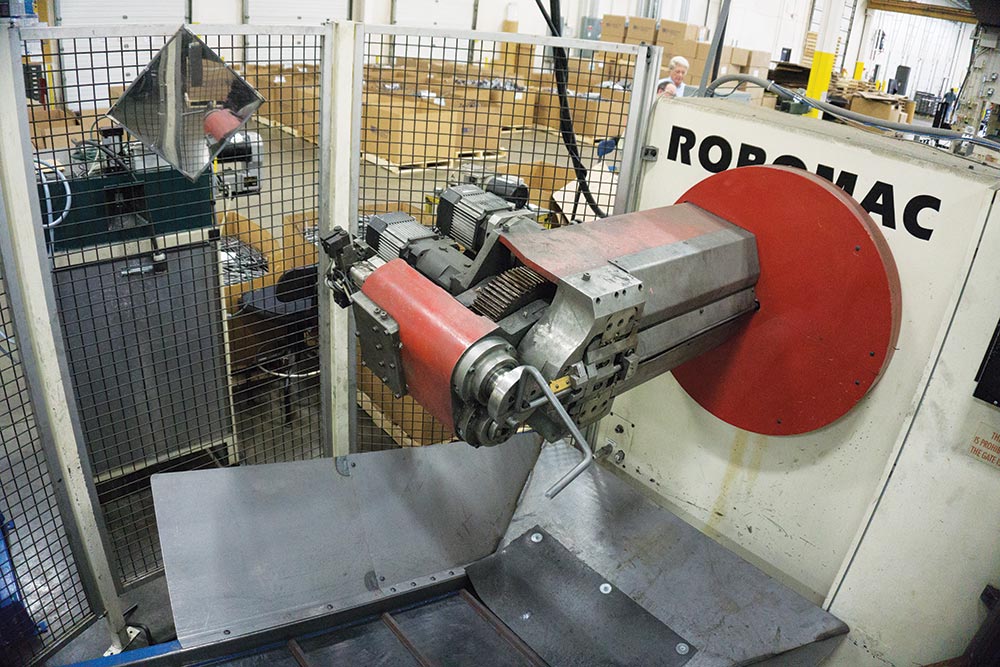

Video preview: This short video shows how wire is uncoiled and fed into the CNC Bending system. CNC programming controls the bending head which moves freely around the wire. Interested in seeing our complete video? Click Here.

Wire Form Material Capabilities:

Wire Form Finishing and Secondary Operations:

K-TEK is a division of Griffiths Corporation which was founded in Minnesota as a short run metal stamping company in the mid-1960's.

K-TEK Wisconsin started in the early 1980's and grew out of their customer's need for a full-service supplier.